Following are the Product categories offered

by ASK and details of specific Projects:

Special Purpose Machines (SPM) are those machines which are not

available off the shelf and are designed & tailor made as per specific

customer requirements.

Depending on the required specifications, ASK Innovations can

design and manufacture special purpose machines for a large range of

applications.

With our expert design and manufacturing team, ASK Innovations

works closely with our customers to assess and understand the needs

and expectations of each project, offering a complete solution to

efficient and cost-effective production processes. The bespoke

machines are custom built and automated to meet your needs on

specified machine capabilities.

The Auto Twisting Machine is developed for

performing one of

the manual processes of

Curling,

in the Synthetic Hair Extension

manufacturing process.

Applicable for Industries like: Hair

Extension Manufacturing

Reduction in the overall time to perform curling

(twisting) of one set of Hair extensions by 40%. that

will help to produce significant bottom- line results

Consistent Production rate. No person to person

variation or Loss of productivity

No person to person variation in product aesthetics

Consistent quality output (Consistent curling /

styling across the production batch)

Reduction in time to develop the operator to

operate the machine for curling as compared to

earlier development period of new labourer to

learn the manual curling process and achieve

desired quality and speed

Machine can be allocated to Low Skilled operator

due to its ease of operations

Machine structure can be customised based on

product variants and can also have different

change parts for minor size variations

Auto Insert Feeding mechanism (a kind of a manipulator) is developed to reduce the cycle time of Injection Moulding process, in which inserts are placed on mould before Mould shot. It helps in increasing the output from Moulding machine. This mechanism reduces the waiting time of machine between each mould shot.

It helps operator to pre-load the inserts on a parallel mechanism (insert holding device) and then auto feeds these inserts precisely on desired location using pneumatic based Manipulator system.

Reduction in the overall cycle time by 30% to 40%

(which earlier was high due to waiting of machine

during manual insert loading)

Safety built-in the mechanism structure and

manner of operation

Easy Loading & Unloading of Parts.

ASK Innovations has complete capability to design and develop

industrial testing and inspection machines / equipment for today's

high-speed manufacturing operations

Based on the process requirement, whether you need a testing

gauge machine or you require an entire system dedicated to one

specific critical test - we can design and build custom testing &

inspection stations and automated systems to help make sure your

product passes the test before it ships.

The High Voltage(HV) and Open Circuit

(OC) testing machine, is custom designed

for testing of STATOR at High Voltage of

electric supply. This SPM works on the

basic principle of indexing, which ensure

safe positioning of a workpiece at a

precise angle or at a precise interval of

rotation, for the machine to perform its

desired testing operation.

Applicable for Industries like:

Fan Manufacturing (All types),

Generators, Alternators, AC / DC

Motors

Guaranteed Safety of Operators

Safety built-in the mechanism structure and manner of operation

Double safety of Operator Isolation and guaranteed part contact

Testing operation automated

Easy Loading & Unloading of Parts

OC Inspection at High Speed via Dedicated & Calibrated equipment

Overall high-speed output with high accuracy

Data Logging of Every part with testing result

Deskilling of critical testing Process

Machine structure can be customized based on

product variants and can also be developed for

multi-size Stator testing

- Compact size & Optimum Floor space

- Usage of Standard components

- Can handle different Stator variants

- In process Heating

- As per best industry practices

- Industry Standard application for Resistance,

Heating & High Voltage testing

Ultraviolet (UV) is a form of electromagnetic radiation. Short-wave UV light damages DNA of pathogens and sterilizes surfaces with which it comes into contact.Broad-spectrum UV-C light, which has a wavelength of between 200 to 280 nanometers (nm), is highly effective at killing bacteria and viruses by destroying the molecular bonds that hold their DNA together. ASK Innovations offers a range of UV-C products, which use unique technology to deliver a fast and effective germicidal dose of continuous waves of UV-C energy

UV-C Tower is an effective Room Disinfection device. It is used to thoroughly disinfect enclosed rooms within a few minutes.

UV-C Arm is a manually driven disinfection device for focused germicidal dosage.

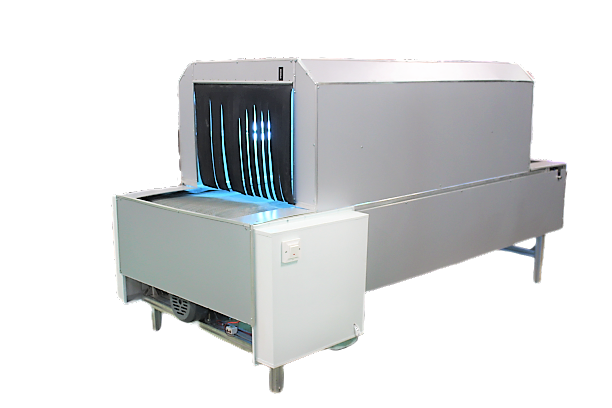

UV-C Tunnel is a conveyor-based disinfection solution used for disinfection of material before entering a premise.

*Specifications mentioned are for standard product which can be customised as per application & customer need

UV-C Gate is a unique Walk Through product to disinfect human beings while entering any premise using UV-C light. This UV-C Gate is also equipped with Disinfection sprinklers to ensure proper sanitization.

UV-C Box is an enclosed device for disinfection of small size items.

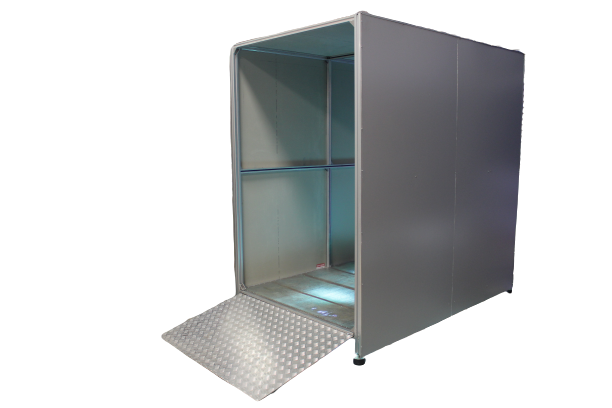

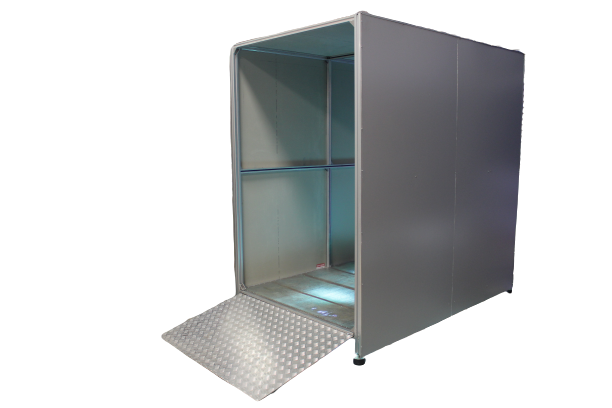

UV-C Wardrobe is a customised encloser for disinfection of garments and similar items.

UV-C Chamber is an enclosed device for disinfection of medium to large size items.

ASK Innovations provides to its clients

a variety of custom built & advanced

Material handling and moving solutions.

An Industrial manipulator is a

machine with a rigid steel arm that

allows complex tilts and rotations,

especially when the product being

moved is handled outside it's centre

of mass. A human operator controls

the machine, allowing for easy and

precise movement of the

manipulator to lift, lower and

otherwise transport a product / part.

Conveyor Systems are mechanical

devices or assemblies that transport

material with minimal effort. There are

many different kinds of conveyor

systems which usually consist of a

frame that supports either rollers, wheels,

or a belt, upon which material moves from

one place to another. They may be powered

by a motor, by gravity, or manually.

Low Cost Automation (LCA) means application of

innovative and breakthrough ideas to achieve

automation in manufacturing lines at affordable

cost, ensuring flexibility to change. It is a technology

that creates some degree of automation around the

existing equipment, tool and methods, using mostly

standard components available in the market.

With its expertise on Lean Manufacturing and

Karakuri, ASK Innovations can develop these low

cost mechanisms which require low power, low

maintenance and having a ROI within 1.5 to 2 years.

We can develop a customised

mechanism and can also serve our

clients with standard products like:

Our precision tooling solutions assist in meeting

bottom line manufacturing goals of repeatability,

consistency, accuracy, and cycle time reduction

At ASK Innovations we Design & Manufacture high

quality Jigs and Fixtures that allows you to produce

more efficiently. Our team along with our

Technology partners have developed superior

know-how to build fixtures and jigs to hold and

support parts being machined to fine tolerances.

Fixture is a device which holds and locates a

workpiece during an inspection or for a

manufacturing operation. It does not guide the tool.

It comprises of specially designed work holding

devices, which are clamped on the machine table to

hold the work in position. The tools are set at the

required position on the work by using the gauges or

by manual adjustment.

Jig is a device which holds and locates a workpiece

as well as guides and controls one or more cutting

tools. Usually a Jig comprises of a plate, structure

or box, made of metal or non-metal, having

provisions to hold the component in identical

positions one after the other and then guiding the

tool in correct position on the work.